Part of the models is made within our own model shop and the other part is outsourced to our partners. Many years of experience guarantees the accuracy of our models. The material for the individual and small series is wood, while for larger series of models are made from aluminum.

All models are equipped with an identification number, which serves for later identification of the samples and for their traceability after the issuance of quality certificates.

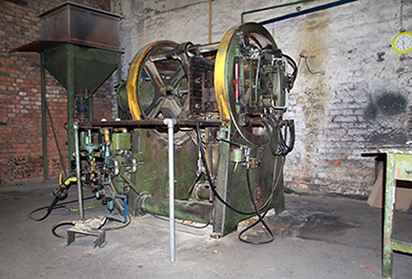

It is primarily used for small-series production of smaller castings. A bentonite sand mixture is used for molding. Sand cores are made by the:

- CO2 process

- chronik process

After the form is made and the core is placed, the upper and lower molds are mounted and weights are placed. The casting process takes place on a roller conveyor.

The production of larger castings up to (250 kg) in individual and small series production takes place manually. Molding is performed using a bentonite sand mixture.

Making a core using the chronik process.

Casting is performed in 100kg, 250kg and 500kg pots.

After casting, the cleaning is commenced with. Castings are cleaned by sandblasting and shot blasting.

Based on customer requirements, castings are painted after cleaning with basic paint.

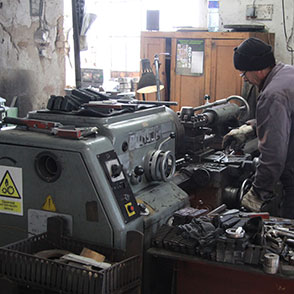

Upon request, mechanical processing is possible in our own mechanical processing workshop. Thanks to a wide network of subcontractors, we are able to offer complete processing according to customer needs.